iKvant – Production Automation and Management System

iKvant – Overview

Production with top effectivity

iKvant system automates management and maintenance of production. System provides full control over production process from planning to marking of completed goods and shipment of products to the customer. System is intended for small and medium-sized enterprises of the light and food industry. System minimize efforts and increase management capabilities by giving whole real time workflow information and controlling tools to affect it.

Sales with maximal profit

iKvant automates all stages of the production cycle and makes it orientated to maximal sales. This includes workflow optimization according to received customer’s orders priority, real time information and management of inventory stock for finished goods. System includes advanced tools for work of the sales department. At any time sales managers are informed about ordered goods progress, loading and shipments to customers.

Performance best possible

iKvant includes monitoring and analytics modules, which allows you to identify bottlenecks in the current production process, and give actual information for monitoring and self-control to production-level personnel to ensure the implementation of established production plans. Full flexible control over the details of the technological process allows to maintain maximum economic efficiency of the enterprise even in the event of a rapid change in market conditions.

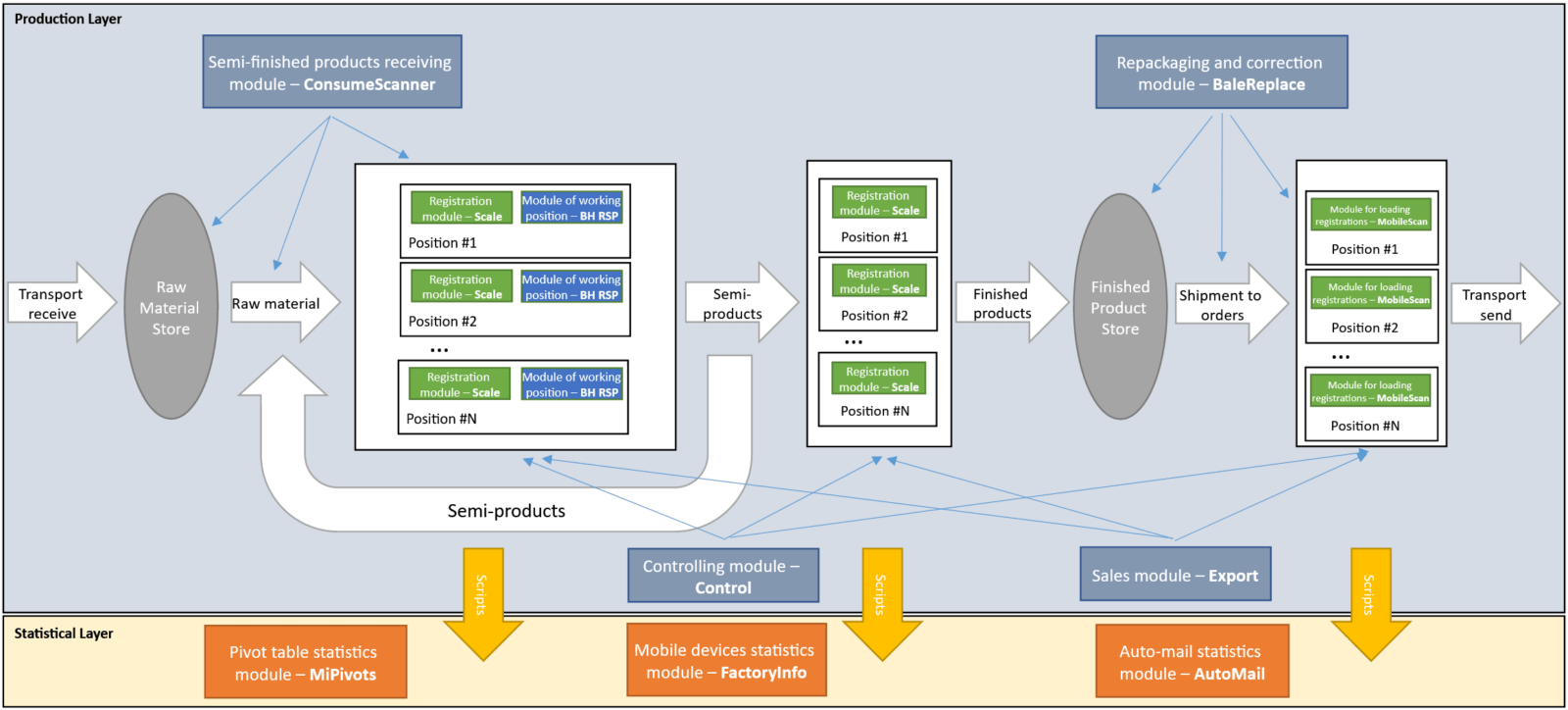

Product Structure

Production system in its advanced version providing extended solution for such important factors of production workflow as workers productivity and material movement through warehouse for all grades in dedicated cages.

For workers there will be automatically provided information about personal plan to achieve for the shift and practically handled amount of material. System is handling data and actual performed plan for workers productivity collected at all production working places and individual working positions.

For collection of trolleys with materials movement status there supported scanning of trolleys with integrated barcode or RFID tag at each working place and single working position. There could be also a dedicated position of trolleys loading and unloading at chosen areas of warehouse.

These actions support allows to count handled amount of goods at working positions at each moment of time, compare it to actual time moment taken shift plan, evaluate individual worker’s performance, to observe location of trolleys and availability of needed raw material at working position’s input.

All these steps are supported with additional automation modules, which could be integrated in chosen subsets to individual positions in selected set or for all positions of the factory.

It’s needed to put attention to special point of presented economical advantage of used technology in this implementation due to wide usage of Raspberry platform computers as head carrier of individual working positions automation. This effective solution allows to reduce expenses significantly and still keep all needed performance with getting even higher stability and secure run of factory position automation dedicated to operate on single task, which uses resources most effectively information.

iKvant – Moduls

-

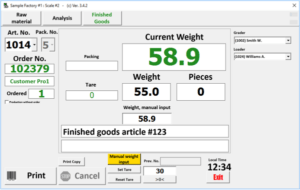

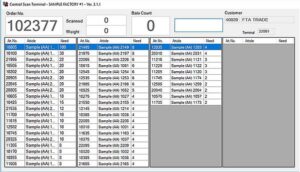

Registration module – Scale

Labeling and registration module

Making of production and semi-production items labeling and registration.

-

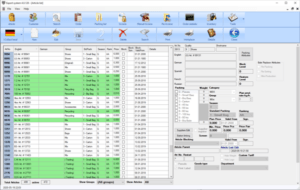

Sales Management Module

Sales management module

Section “Sales” allows to perform orders creation and management system with support of full sales process from order to invoice management and basic statistics browsing. Also it makes editing of connected reference lists as customers, articles of finished goods, etc.

-

Module for loading registrations – MobileScan

Orders loading module

System module is loading and shipment procedures service tool, which is responsible for scanning and collecting items of finished goods to orders in loading procedure before shipping of the order.

-

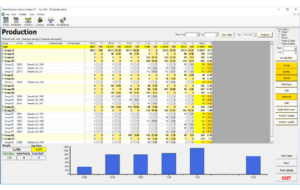

Controlling module – Control

System management module

This module is a combined console of system management at level of real time production statistics and managing production for finished and semi-goods, goods storage buffers, production semi-goods articles, workers and workplaces, loadings and active orders existing in the system.

-

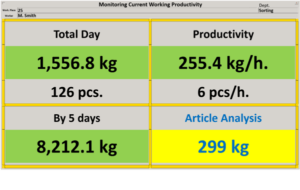

Monitors

Working position monitors

Sifferent modules of real time performance and goal fulfilment demonstration to workers.

-

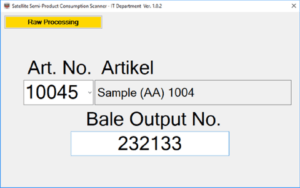

Semi-finished products receiving module – ConsumeScanner

Semi-products consuming module

Semi-goods consumption registration and consumption management module

-

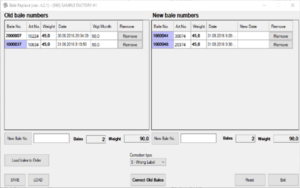

Repackaging and correction module – BaleReplace

Products management and revision module

This module serves for changing of production items status and goods inspection.

-

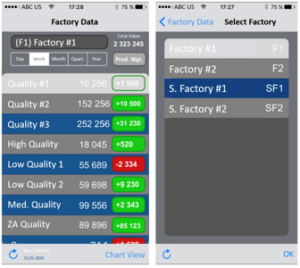

Mobile devices statistics module – FactoryInfo

Mobile statistical module

Statistic browsing module – allows to provide system statistics collected in data hub to linked user devices operating with iOS.

-

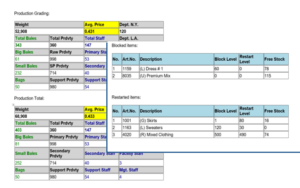

Auto-mail statistics module – AutoMail

Statistical module

These modules are responsible to provide all chosen users configured to receive this data in email message in comfortable and regular way.

-

Working place monitor module – WM RSP

Teamwork monitor module

Teamwork monitor module allows to display and register teamwork of a number of working positions combined together at single working place.

-

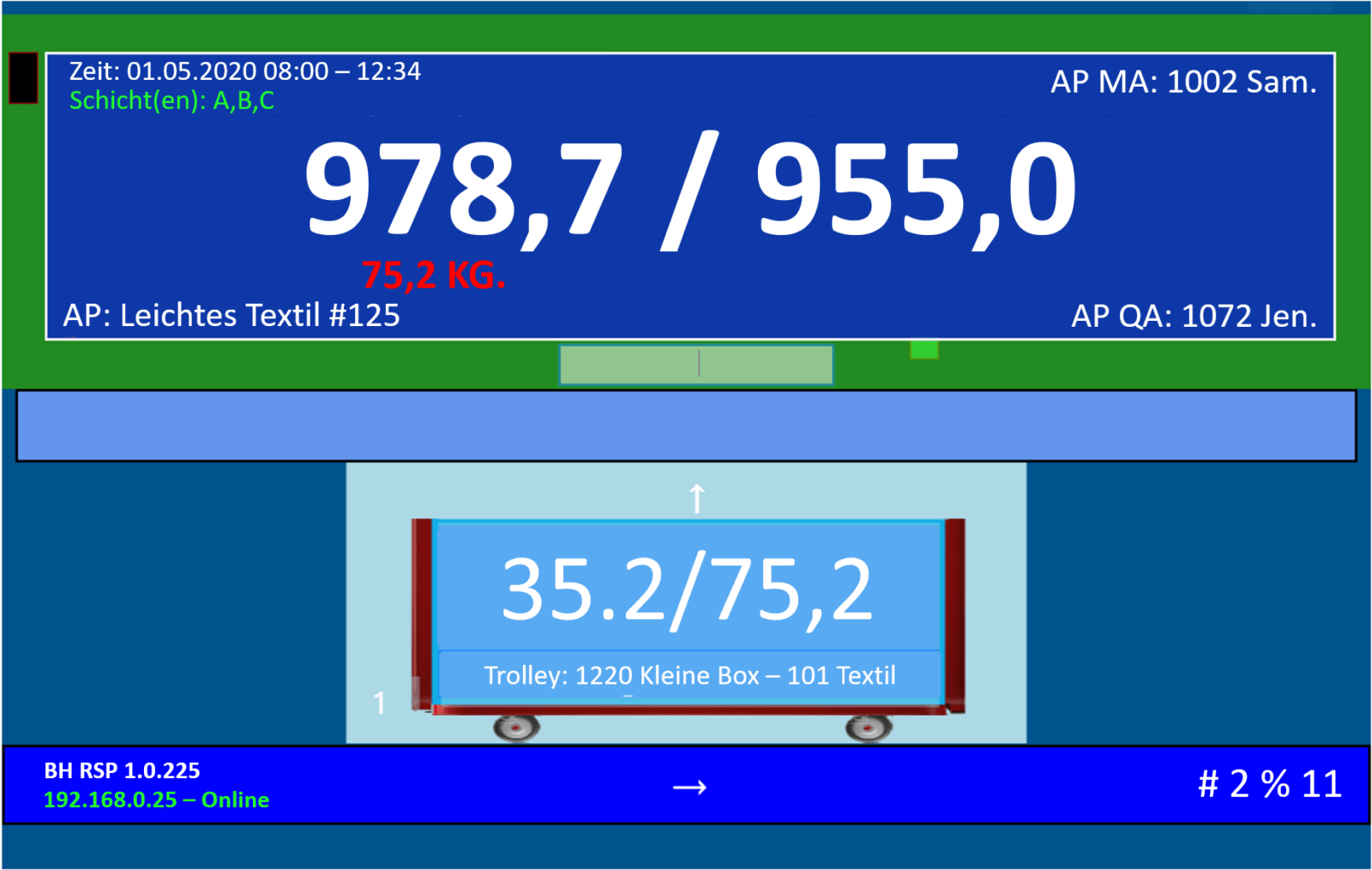

Monitor module of single position – BH RSP

Single Position Monitor

Single position monitor module allows to display and register work of single working positions

-

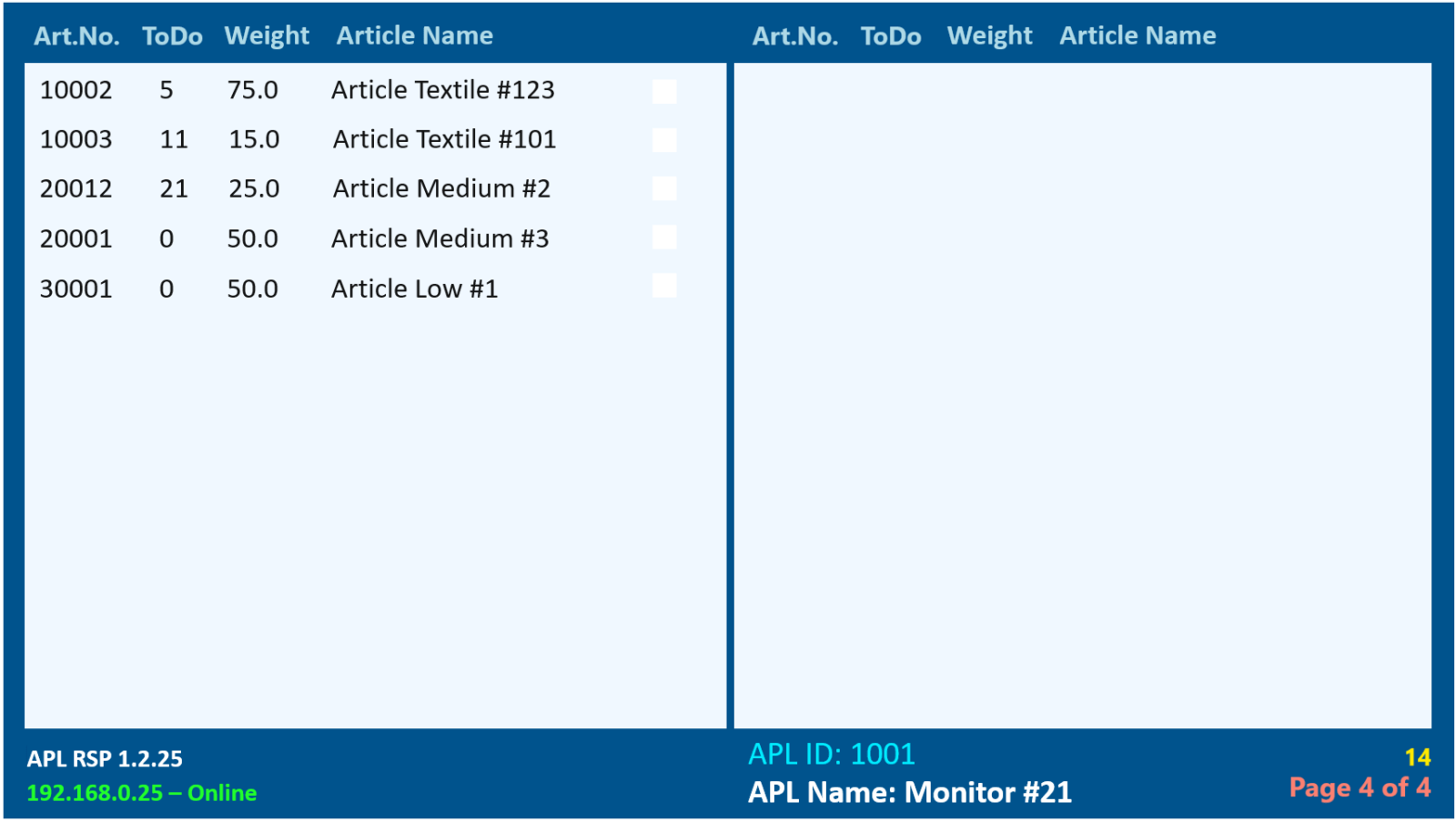

Module article viewer – APL RSP

Self-monitor module

This module displays current information about the production schedule of items.

-

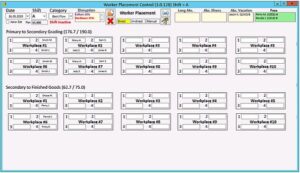

Worker Placement Module – WP

Workers placement module

This module provides shift managers with tools to register, browse and control a lot of parameters

-

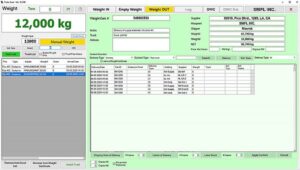

Module of logistic management – TrailerScale

Logistics module

This module manages logistic input and output of material from the factory.